Hydrogen (H2) molecules are the smallest molecules in the universe — one of many factors that present containment challenges for maintaining the integrity of underground H2 storage capabilities. NETL researchers are devoting special care and study to understanding how best to safely store H2 in cement-sealed underground geologic formations.

The work is part of NETL’s participation in a multi-national laboratory effort known as Subsurface Hydrogen Assessment, Storage and Technology Acceleration (SHASTA). The Department of Energy’s (DOE) Office of Fossil Energy and Carbon Management established SHASTA in 2021 to explore H2 storage opportunities in geologic reservoirs. In addition to NETL, DOE labs participating in SHASTA include the Pacific Northwest National Laboratory, Lawrence Livermore National Laboratory, and Sandia National Laboratories.

Hydrogen is emerging as a low-carbon fuel option for transportation, electricity generation, manufacturing applications, and clean energy technologies that will accelerate the United States’ transition to a low-carbon economy if underground storage of H2 can be realized.

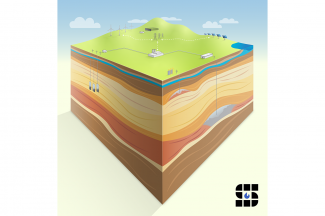

Large-scale storage of H2 can be achieved by using underground resources like how natural gas has been stored for the past century. Underground hydrogen storage has the potential to provide the storage capacity required for the future hydrogen energy market.

During creation of underground storage facilities, a borehole is drilled and lined with steel casing, which is cemented in place. The primary materials of well construction include steel (carbon and/or stainless), polymer elastomers (polymers with elastic properties), and cement. It is important to understand how H2 storage operations can impact the integrity of each of these three materials.

The compatibility of H2 with steel and other metals has been documented in applications like nuclear waste storage. Research has also been conducted that identifies failure mechanisms in elastomers in downhole environments.

NETL has specific expertise in the study of the third material involved in well construction — cement.

Barbara Kutchko, a senior researcher at NETL who develops advanced cement systems to reduce the environmental footprint of oil and gas drilling operations, is researching how H2 storage operations can impact the integrity of the cement that seals pathways between the surface and underground storage facilities.

“The main challenge for the integrity of wellbore cement is the prevention of gas leakage,” Kutchko said. “Hydrogen is highly mobile in the subsurface and will potentially leak through faulty wells. And hydrogen has the highest diffusion rate of all gases because it is the smallest molecule in the universe. That’s why cement integrity must be maintained throughout all phases of underground storage.”/p>

Diffusion is the movement of individual molecules of a substance through a semipermeable barrier.

“We believe that diffusivity, rather than reactivity in cement will be the challenge to effectively store hydrogen underground,” Kutchko added.

As a primary pathway between the surface and underground storage complex, wells must also endure stresses created by site operations, physical stresses created by injection/withdrawal cycles and constant chemical stresses all while maintaining structural integrity. Wells that lose control of injected or extracted fluids may become a human health or environmental hazard if there are leaks into the atmosphere or groundwater in significant quantities.

The work of NETL and its SHASTA collaborators is focused on understanding and addressing all the challenges involved with underground storage so that H2 can assume a larger role in the effort to transition to a net-zero carbon economy.

NETL drives innovation and delivers technological solutions for an environmentally sustainable and prosperous energy future. By using its world-class talent and research facilities, NETL is ensuring affordable, abundant and reliable energy that drives a robust economy and national security, while developing technologies to manage carbon across the full life cycle, enabling environmental sustainability for all Americans.